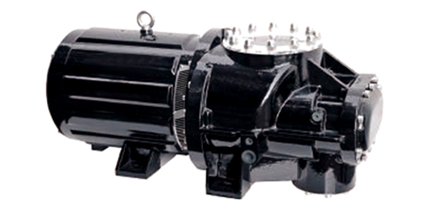

- BUMATEC has applied built-in structure for PM (permanent magnet) motor & air end which is able to make the compact size of air compressor. Because of direct connection of two shafts, the mechanical loss is eliminated and the feature is simple and compact. Permanent magnet motor has no motor bearing, and realize transmission efficiency of 100 %, and high efficiency permanent magnet NdFeB, do not loss excitation even 120 ℃, and increase the durability. Inverter dedicated enameled wire that is corona discharge resistance is adopted for stator coil, which has outstanding insulation performance and durability

-

HF pm motor without bearing, shaft directly connection, embedded integrated design

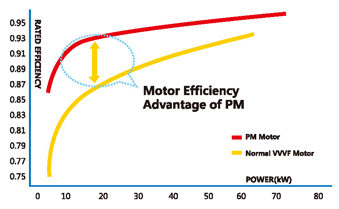

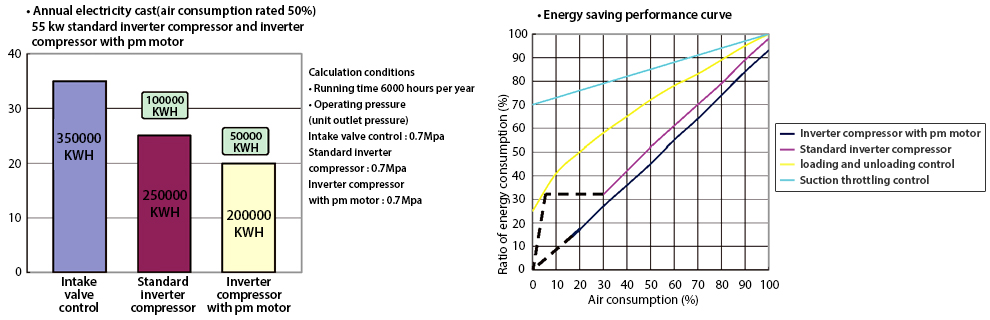

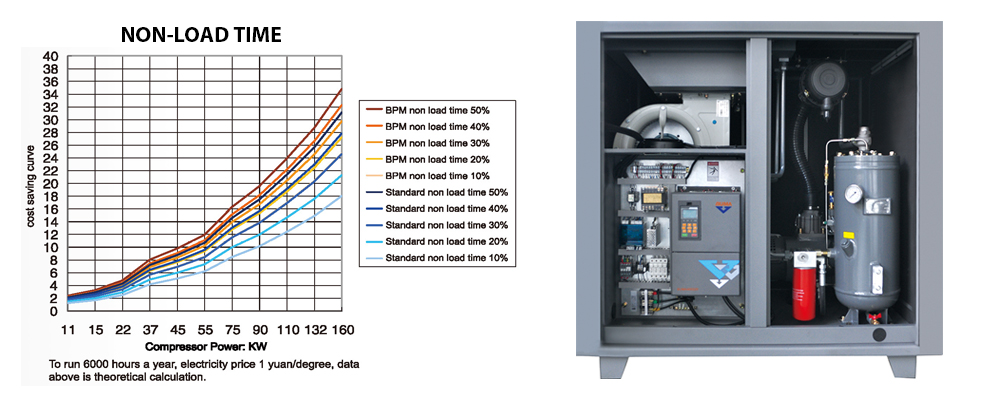

- The motor revolution speed can be adjusted by variable frequency control in accordance with air demand. The energy saving effect is prominent compared to normal motor with fixed revolution. With application of PM motor, the energy saving rate is increased from 6 to 7 % compared to ordinary inverter compressor which is not equipped with permanent magnet motor. It also has an advantage in low load range. BPM series air compressors can be operated in wide range of revolution speed, and the energy saving rate is 42 % better compared to ordinary compressors of frequency fixed.

-

The answer is 25 to 44 %. the energy consumption rate of air compressor in a factory could be more than 40 % from whole energy consumption, this BPM series can significantly reduce energy consumption. It can control production of air volume by variable speed control in accordance with actual demand of compressed air.

- Eliminate the inefficient conversion process from unload to full load.

- Applied permanent magnet motor, energy saving is 6 to 7 % higher compared to other ordinary inverter compressor.

- Air end and motor are directly connected in body structure.

- Avoided power consumption when unload status.

- Maintain the fluctuation pressure under 0.01 MPa in the process line.

- Reduced the average working pressure.

- Reduced system leakage.

- Soft start method improved current balance of motor and prevented shock of current.

- Provided free choice range from 4 to 13 bar, hence it can achieved maximum efficiency.

| Model | Motor Power | Flow Meter | Pressure | Lub Oil | Outlet Diameter |

Dimension | Weight | |

|---|---|---|---|---|---|---|---|---|

| (kW) | (HP) | (m³/ min) | (bar) | (ℓ) | L x W x H (mm) | (Kg) | ||

| BPM 15 | 15 | 20 | 0.35-2.30 | 8 | 10 | G3/4" | 1150×850×1100 | 350 |

| 0.31-2.03 | 10 | |||||||

| BPM 22 | 22 | 30 | 0.56-3.71 | 8 | 12 | G1" | 1300×950×1270 | 500 |

| 0.52-3.42 | 10 | |||||||

| BPM 37 | 37 | 50 | 1.03-6.86 | 8 | 20 | G1-1/2" | 1550×1000×1380 | 750 |

| 0.91-5.95 | 10 | |||||||

| BPM 45 | 45 | 60 | 1.32-8.79 | 8 | G2" | 1700×1100×1520 | 1200 | |

| 1.16-7.73 | 10 | G1-1/2" | 1550×1000×1380 | 800 | ||||

| BPM 55 | 55 | 75 | 1.63-10.74 | 8 | 40 | G2" | 1700×1100×1520 | 1200 |

| 1.40-9.32 | 10 | |||||||

| BPM 75 | 75 | 100 | 2.07-13.8 | 8 | 50 | 2100×1200×1620 | 1500 | |

| 1.81-12.0 | 10 | |||||||

| BPM 90 | 90 | 125 | 2.45-16.33 | 8 | 60 | DN50 | 2200×1350×1650 | 1900 |

| 2.05-13.65 | 10 | |||||||

| BPM 110 | 110 | 150 | 3.03-20.2 | 8 | 75 | DN65 | 2500×1500×1950 | 2200 |

| 2.69-17.9 | 10 | |||||||

| BPM 132 | 132 | 180 | 3.62-24.1 | 8 | ||||

| 3.21-21.3 | 10 | |||||||